Plastic crushers

Thanks to the applied compact, steel construction and the bearing lubrication system, the crushers offered by us ensure low noise level and quite low power consumption.

The use of appropriate selection of screens and knife systems (with a small gap between them), makes it possible to obtain a repeatable, finely ground fraction of the material. The mills for plastics guarantee safe operation, especially when it comes to quick cleaning and blade replacement. The applied safety switches secure against starting the device when the front panel is opened, whereas the localized emergency stop buttons enable immediate shutdown of the device during operation.

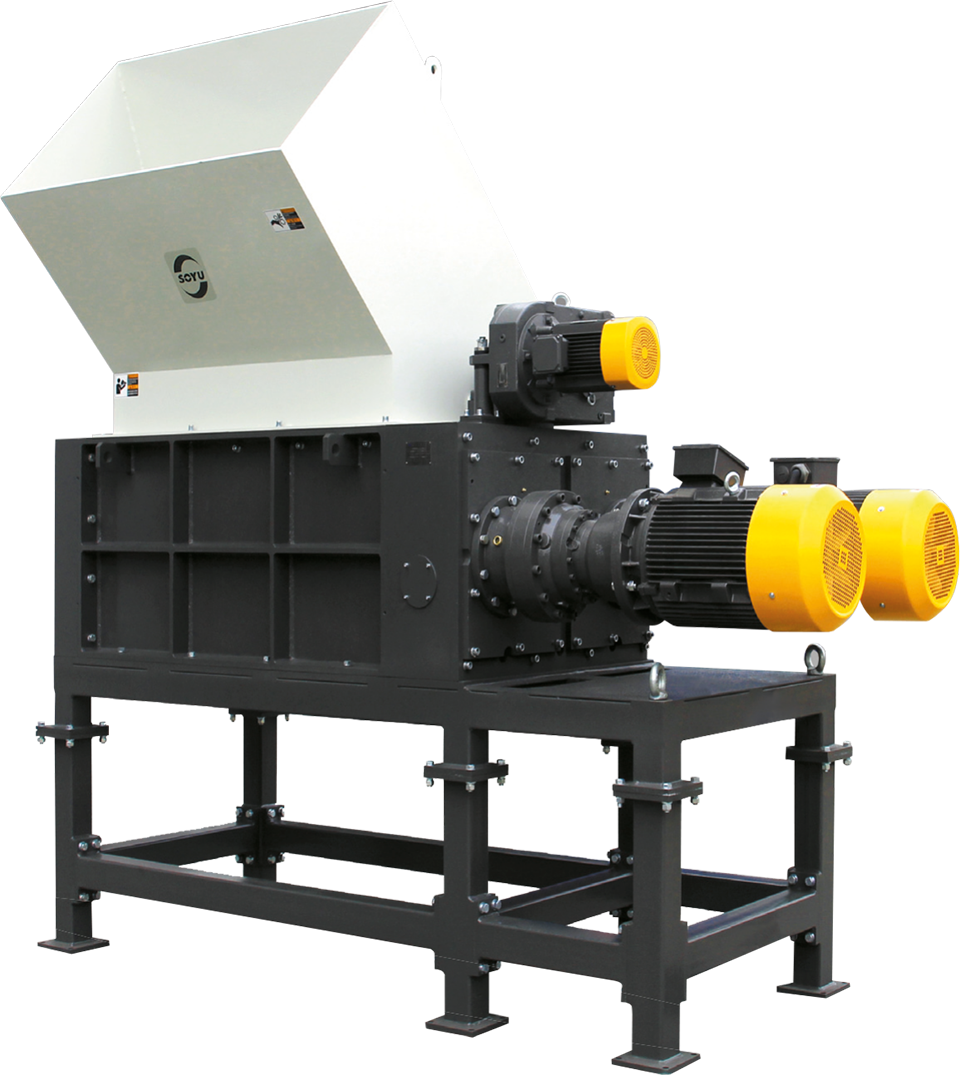

SPC Series Crushers

SPC series crushers are high performance mills with a variety of rotors and feed hoppers suitable for crushing various materials in the plastics industry. In order to meet special requirements at the highest level, the mills have a fully welded steel construction. The V-shaped blade shape improves cutting efficiency and reduces dust when processing plastics. The mills can be used for different materials and capacities and can be additionally equipped with a silencing device and a discharge system. The rotor with hardened surface and the alloy steel design of other parts provide high wear resistance.

SPG Series Crushers

SPG crushers are a series of small mills with compact and mobile design for crushing of plastic waste in recycling processes. Due to their modular design, SPG mills provide easy and direct access for cleaning and allow for easy and quick replacement of the rotating knife. The mills in this series are used in continuous and clean crushing technology, provide low energy consumption, uniform grinding size and low dust. Operational safety is guaranteed by low voltage operation and multiple safety protection provided for these units. The soundproofing inside the mills is responsible for a quieter working environment.

- TECHNICAL DATA

| Model | Engine power [kW] | Feed size [mm] | Number of fixed knives [pcs] | Number of rotary knives [pcs] | Rotor diameter [mm] |

|---|---|---|---|---|---|

| DS 800 | 45 | 500 x 900 | 2 x 2 | 3 x 2 | 420 |

| DS 800 | 75 | 700 x 1100 | 2 x 2 | 3 x 2 lub 5 x 2 | 630 |

| DS 800 | 110 | 800 x 1300 | 2 x 4 | 5 x 4 | 700 |

| DS 800 | 160 | 800 x 1500 | 2 x 4 | 5 x 4 lub 7 x 4 | 800 |

| Model | Engine power [kW] | Feed size [mm] | Number of fixed knives [pcs] | Number of rotary knives [pcs] | Rotor diameter [mm] | Dimensions (LxWxH) [mm] |

|---|---|---|---|---|---|---|

| DS-500F | 11 | 290 x 500 | 2 x 2 | 3 x 5 | 290 | 1100 x 1020 x 1530 |

| DS-600F | 15 | 320 x 600 | 2 x 2 | 3 x 6 | 320 | 1200 x 1110 x 1390 |

| DS-800F | 22 | 540 x 810 | 2 x 2 | 3 x 4 | 540 | 2200 x 1500 x 2300 |

| Model | Engine power [kW] | Feed size [mm] | Number of fixed knives [pcs] | Number of rotary knives [pcs] | Rotor diameter [mm] | Dimensions (LxWxH) [mm] |

|---|---|---|---|---|---|---|

| SPC8022 | 22 | 800 x 400 | 4 | 3 x 2 | 320 | 1750 x 1650 x 1900 |

| SPC8037 | 37 | 1000 x 500 | 4 | 3 x 2 | 320 | 1780 x 1650 x 2400 |

| SPC10045 | 45 | 1000 x 500 | 4 | 3 x 2 | 320 | 1780 x 1900 x 2400 |

| SPC10055 | 55 | 1000 x 700 | 4 | 5 x 2 | 520 | 2070 x 2050 x 3000 |

| SPC12075 | 75 | 1200 x 700 | 4 | 5 x 2 | 520 | 2070 x 2250 x 3000 |

| SPC12090 | 90 | 1200 x 900 | 6 | 5 x 2 | 660 | 2450 x 2350 x 4200 |

| SPC160132 | 132 | 1600 x 900 | 8 | 5 x 4 | 660 | 2450 x 2850 x 4300 |

| SPC160160 | 160 | 1600 x 1000 | 8 | 7 x 4 | 660 | 3000 x 2900 x 4800 |

| Model | SPG 2230 | SPG 2540 | SPG 2650 | SPG 3060 |

|---|---|---|---|---|

| Moc [kW] | 5,5 | |||

| Prędkość obrotowa [obr./min.] | 600 | |||

| Ilość noży obrotowych [szt.] | 9 | |||

| Ilość noży stałych [szt.] | 2 | |||

| Średnica rotora [mm] | 230 | |||

| Rozmiar zasypu [mm x mm] | 230 x 300 | |||

| Średnica sita [mm] | 8 | |||

| Pojemnik manualny | TAK | TAK | TAK | TAK |

| Dmuchawa | - | - | - | - |

| Separator pyłu | - | - | - | - |

| Kaptur dźwiękowy | - | - | - | - |

| Wymiary [mm] | 930 x 680 x 1120 | 1150 x 820 x 1280 | 1200 x 880 x 1400 | 1230 x 1020 x 1520 |

| Waga [kg] | 400 | 550 | 850 | 1000 |

| Model | SQL 400 | SQL 600 | SQL 800 |

|---|---|---|---|

| Moc [kW] | 7,5 | 15 | 30 |

| Prędkość obrotowa [obr./min.] | 580 | 500 | 440 |

| Ilość noży obrotowych [szt.] | 12 | 18 | 24 |

| Ilość noży stałych [szt.] | 2 | 4 | 4 |

| Średnica rotora [mm] | 245 | 290 | 400 |

| Rozmiar zasypu [mm x mm] | 400 x 230 | 600 x 300 | 800 x 400 |

| Średnica sita [mm] | 10 | 12 | 12 |

| Pojemnik manualny | - | - | - |

| Wymiary [mm] | 1,32 x 0,86 x 1,46 | 1,70 x 1,15 x 1,88 | 2,22 x 1,38 x 2,38 |

| Waga [kg] | 430 | 850 | 180 |

| Model | SBM 400 | SBM 600 | SBM 800 |

|---|---|---|---|

| Moc [kW] | 11 | 22 | 37 |

| Moc dmuchawy [kW] | 0,75 | 1,10 | 3,70 |

| Prędkość rotora [obr./min.] | 550 | 495 | 480 |

| Ilość noży rotora [szt.] | 6 | 6 | 6 |

| Ilość noży stałych [szt.] | 4 | 4 | 4 |

| Średnica rotora [mm] | 264 | 330 | 380 |

| Rozmiar zasypu [mm x mm] | 320 x 400 | 390 x 600 | 400 x 800 |

| Średnica sita [mm] | 20 | 25 | 25 |

| Pojemnik manualny | - | - | - |

| Wymiary [mm] | 1200 x 1250 x 1450 | 1450 x 1300 x 1710 | 1820 x 1400 x 2040 |

| Waga [kg] | 650 | 800 | 1620 |

Plastic crushers support the recycling process in its initial stage. The use of this equipment significantly reduces the size of residual materials and waste, which can measurably save production costs. Plastic mills are used to grind both soft and hard plastics such as PP, PET, PVC, foil, rubber or wood.