Washing lines for plastic waste

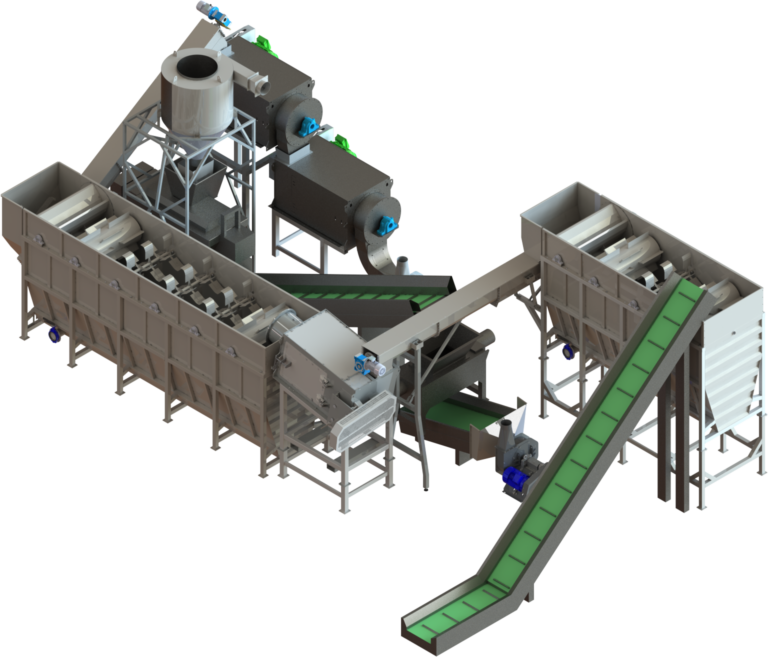

We offer our customers comprehensive services in the field of designing complete washing systems. Preparation of 3D models of process lines according to an individual project gives the possibility to choose the appropriate technical solutions to improve work efficiency, minimise water consumption and energy saving.

In our technological lines, depending on the type of processed material, the washing process is divided into individual stages:

- Shredding,

- Pre-washing and basic washing,

- Mechanical drying,

- Grinding,

The control of the production process of the washing line takes place through the HMI operator panel, where the operator is able to view the current process parameters and change these parameters online. The control system also allows remote access to the machine for service.

Our washing lines are subject to general and special safety regulations and are in accordance with CE requirements. We encourage you to get acquainted with our offer which includes lines for washing plastic waste.

DWFS ® technology applied in our lines is a result of process innovation and uses double circulation in the process of washing plastic processed on the recycling line.

DWFS® technology ensures reduction of flake moisture, allows to improve cleanliness of the plastic flake and at the same time significantly reduces water consumption in the process to achieve positive economical and environmental effects.

Technologically advanced washing lines for PP and PE waste. Our offer includes complete process lines as well as production of individual devices for waste washing such as flotation tanks, washers, centrifuges.