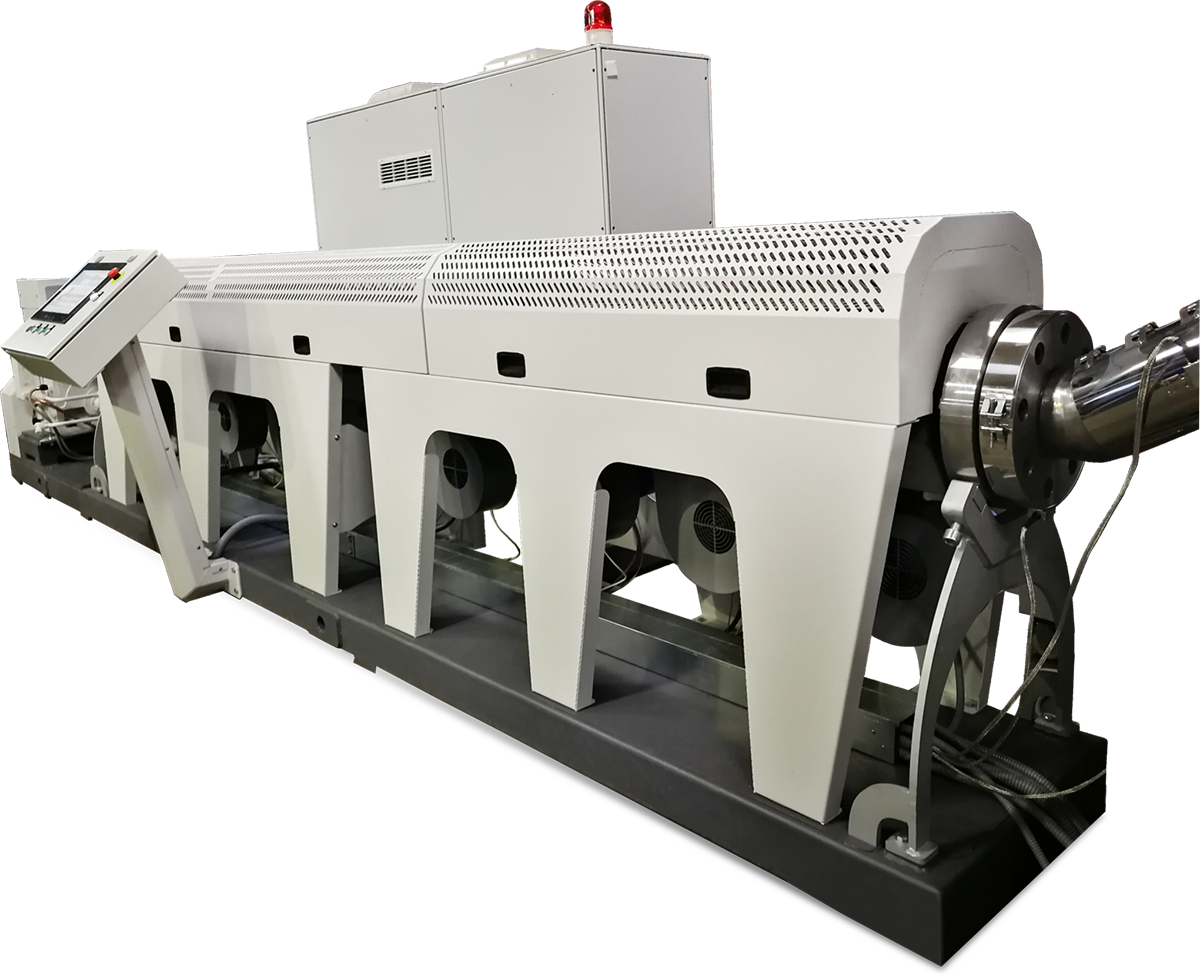

Cascade granulation lines

Cascade granulation line layout consists of a special arrangement of 2 connected extruders and its configuration into one system with the rest of the granulation line equipment. The specificity of granulation in this arrangement implies a milder processing of the material in order to obtain a better quality of granules in terms of plasticity, purity and humidity. This is made possible by equipping the second extruder with a significantly smaller motor power and a shorter screw length of the plasticizing system, thus achieving a longer extrusion distance of the material at a lower shear rate.

In contrast to conventional lines with a single extruder, better quality parameters in cascade extrusion lines are achieved by using multiple (from 3 to 5) vacuum degassing systems. A special role in them is played by a degassing chamber installed at the transition between extruders, which is adapted to work with a many times larger surface of the material than in the standard degassing system in the extruder. Appropriate purity of processed plastic is also obtained through the use of double filtration in the form of two screen changers, installed both at the transition between extruders and at the exit from the second extruder.

Controlling the production process of granulation line is done entirely through the HMI operator panel, where the operator has the ability to view the current parameters of the process and change "online" these parameters. The control system also allows remote access to the machine for management or service.

Machines for recycling plastics (cascade lines for regranulation of plastics) are designed exclusively for the individual needs and requirements of our customers. The devices offered by us for this line are subject to general and specific safety regulations and comply with CE requirements.

We encourage you to familiarize yourself with our offer including cascade granulation lines of KLT-Z series.

- Technical data

| Model | KLT-Z100 | KLT-Z120 | KLT-Z160 | KLT-Z180 | KLT-Z200 |

|---|---|---|---|---|---|

| Extruder 1 motor power [kW] | 110 | 160 – 200 | 200 – 355 | 355 – 500 | 400 – 500 |

| Engine power extruder 2 [kW] | 55 | 70 – 90 | 110 – 132 | 132 – 160 | 132 – 160 |

| Power of compactor motor [kW] | 90 | 110 | 200 – 250 | 250 – 280 | 315 |

| Diameter of Extruder Screw 1 | 100 | 120 | 160 | 180 | 200 |

| Diameter of Auger Extruder 2 | 120 | 150 | 180 | 200 | 220 |

| Length of Extruder Auger 1 [L/D] | 44 : 1 | 44 : 1 | 44 : 1 | 44 : 1 | 44 : 1 |

| Length of Extruder screw 2 [L/D] | 23 : 1 | 23 : 1 | 23 : 1 | 23 : 1 | 23 : 1 |

| Capacity [kg/h] | 350 – 450 | 500 – 700 | 850 – 1100 | 1000 – 1500 | 1500 – 2000 |

Cascade granulation lines are plastic recycling machines which are designed to granulate shredded in the form of films and milled, heavily printed (with a high degree of dirtiness) and higher moisture plastic waste such as PP, PE, LLDPE, LDPE, PS or ABS. Depending on the materials to be processed, cascade lines can have different configurations of equipment.