Plastic extruders

The advanced stage of processing in extruders consists in subjecting the processed material to appropriate physical processes such as densification, compression and forming at high temperatures. Plastic in the form of milled material or film flakes is fed into a hopper or compactor (where it is preheated and compacted) and then supplied to a screw in the extruder barrel.

The rotational movement of the screw transports the material to the plasticizing zone, where it is melted and homogenized under the influence of heat from heating elements (heaters) and friction against the cylinder (so-called homogenization). Homogeneous material is then fed at an appropriate speed to the extruder head, where it is properly formed.

To ensure better plasticization of the printed waste, it is necessary to use a degassing system in the extrusion line granulators. This system ensures effective reduction of the gas produced during extrusion and prevents defects in the form of air bubbles on the final product.

The division of the plasticizing zone of the cylinder system into heating zones controlled by temperature regulators and equipping these zones with special cooling systems (water or fan) ensures that the processed material reaches the right temperature and density, and thus its effective plasticization. High quality of the final product is also provided by extruders with appropriately selected extruder length and screw pitch and diameter. The specificity of production and extrusion of the processed bulk material, determines in addition to the design and dimensions of the plasticizing screw also properly matched to these parameters screw speed and installed power of engines.

Control of the granulation line production process is done entirely through the HMI operator panel, where the operator has the ability to view the current parameters of the process and change “online” these parameters. Control additionally enables remote access to the machine for management or service.

For customers who value aesthetics in a compact housing we offer extruders of QUALIA series. Specially designed external covers of this series ensure convenient and ergonomic access to particular parts of the device, while increasing its safety level in use.

Extruders manufactured by us are subject to general and specific safety regulations and comply with CE requirements. We invite you to familiarize yourself with our range of extruders including:

– extruders with a compactor

– extruders with feed hopper

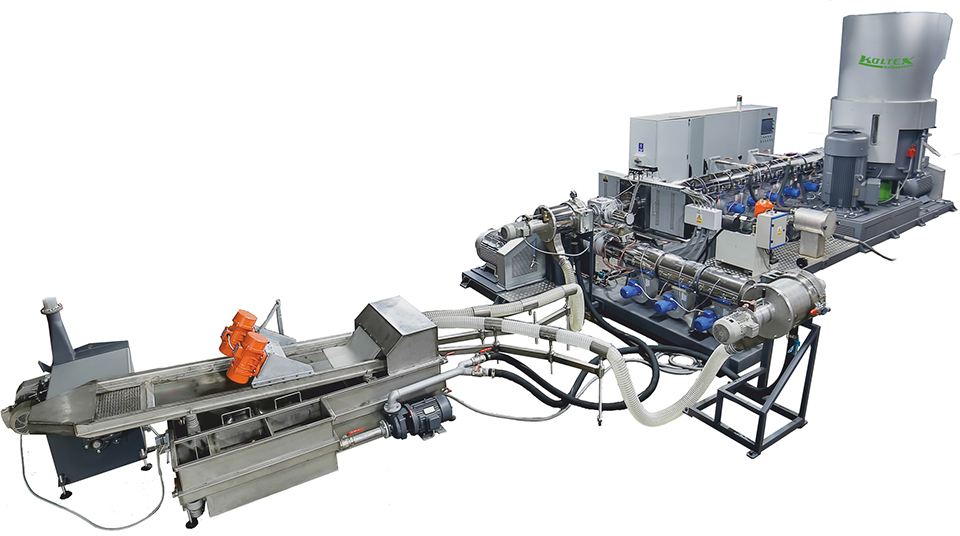

– cascade extruders

Extruders for plastic granulation are the main devices of the granulation line, responsible for agglomeration, homogenization and proper shaping of plastic material for further recycling stages. Depending on the configuration, ranging from single-screw systems to cascade systems, extruders are designed for granulation of comminuted, lightly and heavily printed plastics such as PP, PE, LLDPE, LDPE, PS, ABS in the form of foil and milling.