Screen changers

The principle of operation of plate filter screen exchangers is based on alternating, automatic or manual use of various interchangeable filter screens, placed on specially designed for this purpose sliding plates. In order to press the material through the sieve, the sieve plate is introduced into the filtration chamber of the device from where it is discharged only after the sieve is heavily contaminated. Increasing mass pressure inside the filter chamber becomes a signal for manual, or with the help of a mass pressure sensor, automatic change of the replacement screen.

Screen changers are equipped with a hydraulic unit and accumulator (condenser), so moving the screen plate does not require stopping the extruder. Heaters located in the body of the screen changer ensure constant temperature and proper fluidity of the filtered material.

Reciprocating filter screen changers consist of double-piston filters with a large filtration area, where 2 circular filter screens are wrapped around a support rail and are arranged on a separate piston in parallel. The reciprocating screen changer provides uninterrupted operation when changing screens and has sufficient capacity to take up the total flow of material. It is designed with a pre-filling and venting mechanism, which, in order to avoid air entrapment and bubble formation in the end products, occurs immediately after the screen change. Piston filter flow channels have very good flow properties so that they work well in almost all types of thermoplastics and function excellently at high pressures of 400 bar (40 MPa) without affecting product quality.

Our company also manufactures manually controlled screen exchangers, which are simpler in construction and designed for materials with a low degree of contamination. We also offer our customers comprehensive advice, technical service and spare parts. We invite you to get acquainted with our offer of filter screen exchangers including JC and PFWS series.

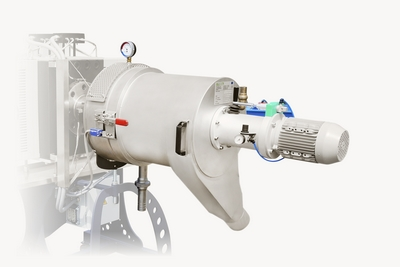

PISTON SCREEN CHANGER

- cleaning of plastic on the principle of pushing/pressing through the filter mesh placed around the piston rod of the actuator

thanks to equipment with a hydraulic unit, quick change of screen position and its replacement

smooth continuous production without having to stop the machine

straight rectangular filter mesh used

AUTOMATIC PLASTIC FILTER (MESHLESS)

- provides an extremely effective solution for the filtration of plastics such as PP, PS, PE, PET or ABS and is designed to achieve better recycling end products and the resulting finished products.

the filter, which operates in a continuous mode, automatically and continuously removes contaminants, without the need for frequent replacement of filter nets as in the case of screen changers. – the device has a high level of automation and can be applied to many types of machines after making appropriate adapters.

The operation of the double rotary plastic filter is based on the use of a double set of cutting knives, hole pads on the surface of which rotary cutting knives continuously remove contaminants and discharge them to the outlet valve in the lower part of the device. The filtered plastic mixture is further transported through appropriate channels to the granulation system.

The operation of the cutting knives is regulated automatically and controlled by measuring the pressure of the melted plastic in the filter chamber.

thanks to the use of an automatic filtering solution, the large filtration area remains constant, which ensures a constant flow pressure and stability of the plastic parameters

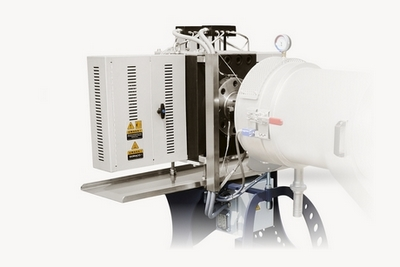

HYDRAULIC DRAWER (TWO-DRAWER) SCREEN CHANGER

- The purpose of the hydraulic two-position drawer screen changer is to filter impurities found in plastics.

The screen changer has two places where a “mesh / filter” can be installed to clean the polymers that are “pushed / pumped” through this screen.

The filter / screens are installed between the extruder and the granulation system on a moving drawer driven by a hydraulic system.

the offered screen exchangers are equipped with a hydraulic unit and an accumulator (condenser), so moving the screen window does not require stopping the extruder.the exchangers do not require any adjustment to improve tightness, as they have a self-sealing system.

| Model | Moc grzewcza [kW] | Średnica sita [mm] | Maksymalne ciśnienie tworzywa [MPa] | Wydajność [kg/h] |

|---|---|---|---|---|

| JC-50 | 4 | 50 | 25 | 50 – 100 |

| JC-100 | 6 | 100 | 25 | 100 – 200 |

| JC-120 | 7 | 120 | 25 | 150 – 250 |

| JC-150 | 8 | 150 | 20 | 250 – 400 |

| JC-200 | 10 | 200 | 20 | 350 – 600 |

| JC-250 | 12 | 250 | 20 | 500 – 800 |

| JC-300 | 15 | 300 | 20 | 500 – 800 |

| Model | Wymiary sita [cm] | Powierzchnia filtracji [cm2] | Maksymalne ciśnienie tworzywa [MPa] | Moc grzewcza [kW] | Wydajność [kg/h] |

|---|---|---|---|---|---|

| PFWS-500 | 29,8 x 8,5 | 250 x 2 | 35 | 5 | 350 |

| PFWS-1200 | 42,4 x 13 | 600 x 2 | 35 | 9 | 800 |

| PFWS-1600 | 47,1 x 17 | 800 x 2 | 35 | 11 | 1000 |

| PFWS-2000 | 53,3 x 19 | 1000 x 2 | 35 | 12 | 1400 |

| PFWS-3000 | 64,4 x 22,5 | 1500 x 2 | 30 | 16 | 2000 |

| PFWS-4400 | 88 x 25 | 2200 x 2 | 30 | 20 | 3000 |

| PFWS-5650 | 94 x 30 | 2827 x 2 | 30 | 21 | 3700 |

Offered screen exchangers are equipped with hydraulic unit and accumulator (condenser), thanks to which moving the screen window does not require stopping the extruder. extruder. The exchangers do not require any adjustments in order to improve tightness, as they have self sealing system. We also make screen exchangers which are simpler in construction and controlled manually operated exchangers designed for materials with low degree of contamination.