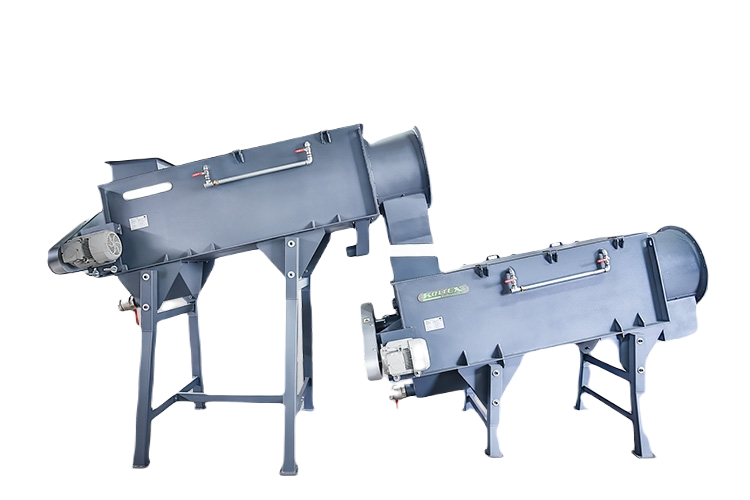

Screw Compactors

Screw compactors allow to effectively save energy spent on obtaining the required degree of moisture of the processed material. Compactors are devices designed to remove moisture by pressing and raising the temperature of shredded, washed film waste and are installed at the ends of film washing and drying lines.

The device is equipped with a feeding hopper, which enables gravitational flake flow to the screw system built inside. A special screw operating in this system allows to compact and squeeze out the material from the contained water by enclosing the system – a perforated cylinder. Thanks to the rotary movement of the screw, the material is transported to the hydraulic screw press located at the outlet of the device, which is the basis of its operation. The high clamping force of the press and the use of special holding jaws ensure that the film flakes obtained from the screw compactor are properly dried and compacted.

After the appropriate configuration of the compactors, it is also possible to work with materials such as PS. In our offer you will find KLM-P series screw compactors. Our devices are characterized by quiet operation and low energy consumption (installed power 22 kW – 55 kW). The screw compactors are subject to general and special safety regulations, and comply with CE requirements.

- TECHNICAL DATA

| Model | Moc silnika [kW] | Wydajność suszenia folii [kg/h] | Moc pompy hydraulicznej [kW] |

|---|---|---|---|

| KLM-PR 500 | 22 | 500 | 1,5 |

| KLM-PR 1000 | 45 lub 55 | 1000 | 1,5 |

Achieving the right degree of drying of processed waste in the plastics recycling process is a key, quite costly in terms of energy, stage that determines the quality of the final product obtained during the entire granulation process on granulation lines.