Shredders

We are an authorized representative in Poland of SOYU shredders, a well-known Chinese manufacturer of shredding machines - Changshu Shouyu Machinery.

Shredding of particularly hard products is possible thanks to compact and optimized design, where implemented technical solutions ensure the highest efficiency of operation. The use of a pushing drawer enables the material to be moved towards the rotor more efficiently and the use of hydraulic pressure makes it easier to shred. In addition, in shredders the appropriate material throughput is achieved by combining the appropriate engine power, size of the feed hopper and working chamber, size of the rotor and the number and quality of cutting knives. Additional work safety is guaranteed by mechanical and electrical protection against overloading. Our shredders are CE certified.

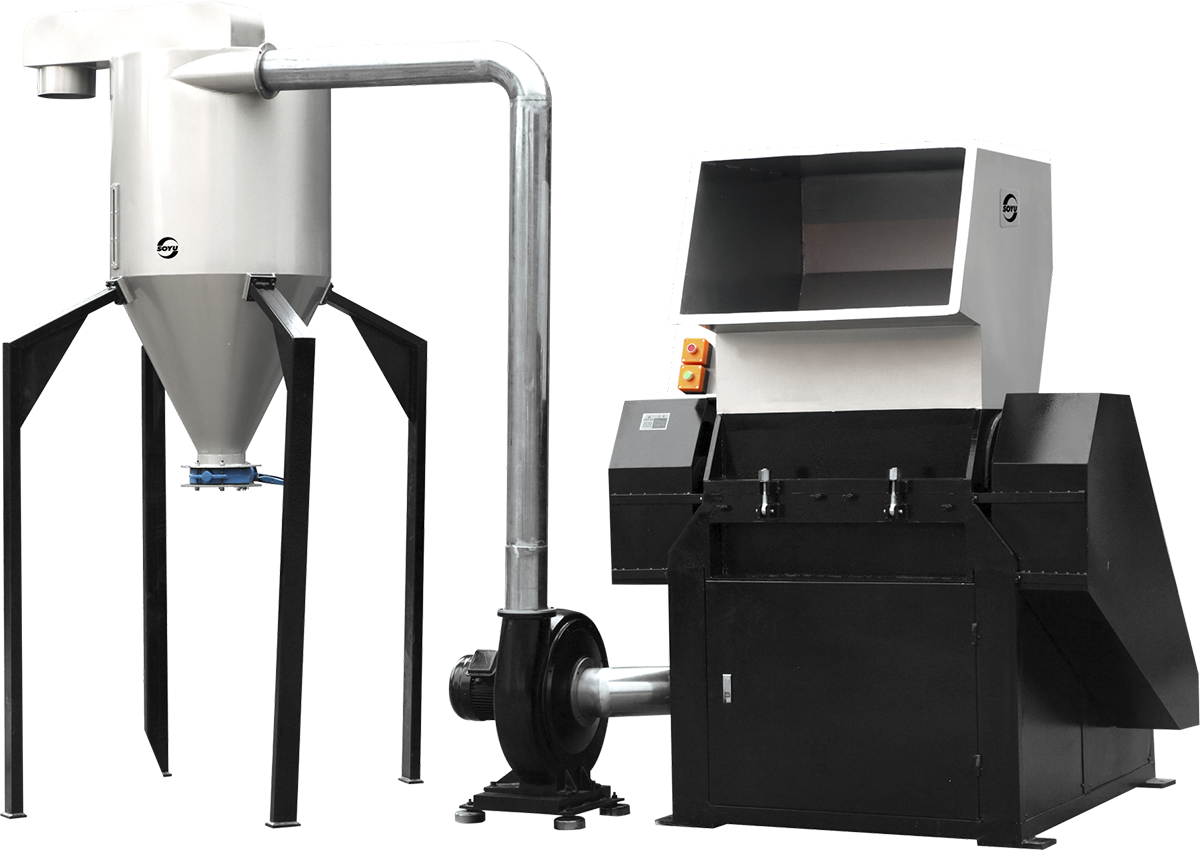

Single-shaft shredders

are versatile machines capable of processing many different materials and are manufactured in many different configurations. The single-shaft shredders have a compact and optimized design and are adapted to shred waste materials such as film, pipes, wood or paper into different fractions depending on the customers’ requirements.

Each of the single-shaft shredder models is equipped with an automatic system protecting the device against overload, using elements of renowned global companies. Equipped with automatic reversing sensors protects the device from overloading and jamming. The machine has a specially designed rotor, which is extremely resistant to wear. The rotor blades are made of high alloy steel, while different rotor blades can be optionally used for different materials and reusable by changing their angles. Designed with split bearing block technology, rotor blades can be changed quickly and easily. Single-shaft shredders are equipped with a push device, a precision-processed, space-saving chamber and a push plate.

We invite you to get acquainted with our range of imported single-shaft shredders SR series.

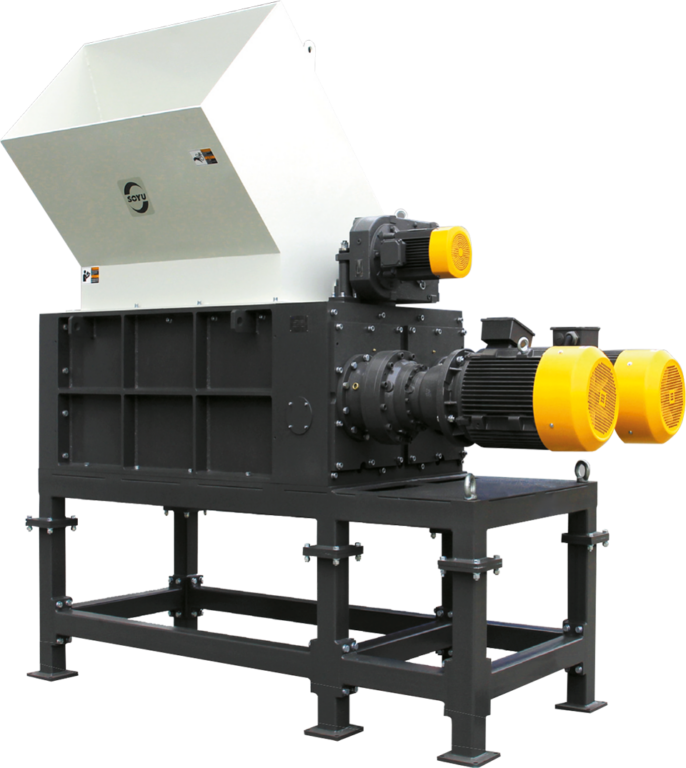

Twin-shaft shredders

are machines with high versatility, thanks to their high torque they can meet various requirements in the recycling technology. The above technical solution is adapted to shredding large and hard materials such as: car bodies, tires, aluminum and steel waste, municipal waste, etc. The installed gears connected to the rotor meet the DIN 5480 standard. The advantages of this solution are high torque combined with low speed, limited noise emission and relatively low maintenance costs. Each model is equipped with an automatic system protecting the device against overload using elements of renowned global companies.

We invite you to familiarize yourself with our offer, including imported twin-shaft shredders of SYU series.

Four-shaft shredders

thanks to many rotors with variable rotation speed are very good for shredding among others barrels and plastic containers, municipal waste, medical waste, hazardous waste, etc. These shredders use planetary gears and the rotors rotate at variable speeds to meet different customer requirements.

The range of four-shaft shredders offered is very wide, starting from FS 66 series, whose type is used to shred lightweight materials such as PET bottles, cartons, plastic containers, etc., to FS 130 and FS 160 series shredders – heavy-duty machines whose blades are made of special alloy steel with high strength, strong anti-wear effect and repairability. For these series, the drive section uses 4 motors and heavy planetary gears to turn the main shafts at different speeds. The characteristics of their drive are low speed, high torque and low noise.

Please refer to our range of imported FS series four-shaft shredders.

- Technical data

| Model | SR 600 | SR 750 | SR 900 | SR 1100 | SR 1400 | SR 1600 | SR 2100 | SR 2500 |

|---|---|---|---|---|---|---|---|---|

| Diameter [mm] | 220 | 400 | 400 | 400 | 400 | 480 | 480 | 480 |

| Rotor revolutions [rpm] | 73 | 73 | 73 | 73 | 73 | 73 | 73 | 73 |

| Length of pressure chamber [mm] | 500 | 820 | 820 | 820 | 820 | 1000 | 1000 | 1000 |

| Number of rotary knives [pcs] | 23 | 33 | 39 | 49 | 60 | 70; 94 | 92; 122 | 112; 150 |

| Number of fixed knives [pcs] | 4 | 6 | 6 | 8 | 10 | 12 | 16 | 20 |

| Number of cutting edges [pcs] | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 |

| Dimension of the cutting chamber [mm] | 510 x 600 | 830 x 768 | 830 x 900 | 830 x 1130 | 830 x 1360 | 1000 x 1590 | 1000 x 2055 | 1000 x 2515 |

| Material picking up height [mm] | 500 | 600 | 760 | 760 | 760 | 950 | 950 | 950 |

| Sieve diameter [mm] | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Hydraulic power [kW] | 1,5 | 2,2 | 2,2 | 5,5 | 5,5 | 7,5 | 7,5 | 7,5 |

| Engine power [kW] | 18,5 | 37 | 37; 45 | 55; 75 | 75; 90 | 75; 90 2 x 45; 2 x 55 | 2 x 75; 2 x 90 | 2 x 75; 2 x 90 |

| Dimensions [mm] | 1850 x 1300 x 1700 | 2700 x 1500 x 2000 | 2700 x 1950 x 2150 | 2700 x 2300 x 2150 | 2700 x 2600 x 2150 | 3300 x 4100 x 2700 | 3300 x 4600 x 2700 | 3300 x 4900 x 2700 |

| Weight [kg] | ok. 1600 | ok. 3300 | ok. 4100 | ok. 4700 | ok. 5600 | ok. 8200 | ok. 10500 | ok. 12500 |

| Model | Moc silnika [kW] | Ostrza [mm] | Średnica rotora [mm] | Ilość ostrzy [szt.] | Wymiary [mm] | Waga [kg] |

|---|---|---|---|---|---|---|

| SYU 1530 | 1,5 | 18,5 | 200 | 14 | 850 x 560 x 1550 | 500 |

| SYU 1940 | 7,5 | 18,5 | 245 | 20 | 1860 x 900 x 1800 | 1400 |

| SYU 1960 | 2 x 7,5 | 18,5 | 245 | 30 | 1950 x 900 x 1800 | 1600 |

| SYU 1980 | 2 x 11 | 18,5 | 245 | 42 | 2180 x 900 x 1800 | 1800 |

| SYU 2360 | 18,5 | 25 | 290 | 24 | 2300 x 1000 x 1950 | 3000 |

| SYU 2380 | 22 | 25 | 290 | 32 | 2500 x 1000 x 1950 | 3500 |

| SYU 23100 | 22 | 25 | 290 | 40 | 2700 x 1000 x 1950 | 4000 |

| SYU 2680 | 18,5 | 40 | 320 | 20 | 2410 x 1100 x 2050 | 4200 |

| SYU 26100 | 22 | 40 | 320 | 25 | 2810 x 1100 x 2050 | 4600 |

| SYU 26120 | 22 | 40 | 320 | 30 | 3010 x 1100 x 2050 | 5000 |

| SYU 3380 | 2 x 22 | 50 | 430 | 16 | 3000 x 1250 x 2150 | 4700 |

| SYU 33100 | 2 x 30 2 x 22 | 50 | 430 | 20 | 3200 x 1250 x 2150 | 5200 |

| SYU 33120 | 2 x 30 | 50 | 430 | 24 | 3400 x 1250 x 2150 | 5700 |

| SYU 41100 | 2 x 30 | 50 | 534 | 20 | 3660 x 1700 x 2650 | 9000 |

| SYU 41140 | 2 x 37 | 50 | 534 | 28 | 4160 x 1700 x 2650 | 10000 |

| SYU 41160 | 2 x 45 | 50 | 534 | 32 | 4360 x 1700 x 2650 | 11000 |

| SYU 50130 | 2 x 55 | 50 | 650 | 32 | 4200 x 2100 x 3000 | 13000 |

| SYU 50180 | 2 x 55 | 50 | 650 | 36 | 5200 x 2100 x 3000 | 14000 |

| SYU 61180 | 2 x 75 | 75 | 800 | 24 | 5400 x 2400 x 3700 | 20000 |

| SYU 61210 | 2 x 90 | 100 | 800 | 21 | 6200 x 2400 x 3700 | 23000 |

| SYU 80210 | 2 x 225 | 150 | 980 | 14 | 7100 x 2900 x 4200 | 26000 |

| SYU 80250 | 2 x 225 | 150 | 980 | 17 | 7600 x 2900 x 4200 | 29000 |

| SYU 80300 | 2 x 225 | 150 | 980 | 20 | 8300 x 2900 x 4200 | 32000 |

| Model | SRSF750 | SRSF900 | SRSF1100 | SRSF1300 |

|---|---|---|---|---|

| Moc [kW] | 2 x 45 | 2 x 45 / 2 x 55 | 2 x 55 / 2 x 75 | 2 x 75 / 2 x 90 |

| Średnica rotora [mm] | 400 | 400 | 400 | 400 |

| Prędkość obrotowa [obr./min.] | 73 | 73 | 73 | 73 |

| Ilość noży stałych [szt.] | 6 x 2 | 6 x 2 | 8 x 2 | 10 x 2 |

| Ilość noży obrotowych [szt.] | (39 + 24) x 2 | (45 + 28) x 2 | (57 + 36) x 2 | (69 + 44) x 2 |

| Komora tnąca [mm x mm] | 1100 x 760 | 1100 x 900 | 1100 x 1130 | 1100 x 1360 |

| Wysokość odbioru [mm] | 680 | 680 | 680 | 680 |

| Średnica oczka sita [mm] | 25 | 30 | 30 | 40 |

| Wymiary [mm] | 2500 x 2700 x 2300 | 2600 x 2700 x 2300 | 3000 x 2900 x 2300 | 3400 x 2900 x 2300 |

| Waga [kg] | 4000 | 5000 | 64000 | 7000 |

| Model | Moc silnika [kW] | Ostrza [mm] | Średnica rotora [mm] | Ilość ostrzy [szt.] | Wymiary [mm] | Waga [kg] |

|---|---|---|---|---|---|---|

| FS 4030 | 1,5 | 18,5 | 180 | 14 | 850 x 600 x 1650 | ok. 600 |

| FS 6650 | 7,5 | 18,5 | 230 | 26 | 1400 x 910 x 1800 | ok. 1000 |

| FS 8040 | 2 x 11 | 18,5 | 245 | 20 | 1860 x 1200 x 2065 | ok. 1600 |

| FS 8060 | 2 x 11 | 18,5 | 245 | 30 | 1950 x 1200 x 2065 | ok. 1800 |

| FS 8080 | 2 x 11 | 18,5 | 245 | 42 | 2180 x 1200 x 2065 | ok. 2000 |

| FS 9080 | 2 x 18,5 | 25 | 290 | 32 | 2300 x 1320 x 3000 | ok. 3500 |

| FS 90100 | 2 x 18,5 | 25 | 290 | 40 | 2500 x 1320 x 3000 | ok. 4200 |

| FS 10080 | 2 x 18,5 | 40 | 320 | 21 | 2410 x 1400 x 2730 | ok. 5000 |

| FS 100100 | 2 x 18,5 | 40 | 320 | 26 | 2610 x 1400 x 2730 | ok. 5500 |

| FS 100120 | 2 x 22 | 40 | 320 | 31 | 2810 x 1400 x 2730 | ok. 6000 |

| FS 100140 | 2 x 22 | 40 | 320 | 36 | 3010 x 1400 x 2730 | ok. 6500 |

| FS 130100 | 2 x 15 + 2 x 22 | 50 | 430 | 20 | 3200 x 1650 x 2930 | ok. 11500 |

| FS 130120 | 2 x 15 + 2 x 30 | 50 | 430 | 24 | 3400 x 1650 x 2930 | ok. 12500 |

| FS 130140 | 2 x 15 + 2 x 30 | 50 | 430 | 28 | 3600 x 1650 x 2930 | ok. 13500 |

| FS 130180 | 2 x 15 + 2 x 30 | 50 | 430 | 36 | 4000 x 1650 x 2930 | ok. 15500 |

| FS 160140 | 2 x 30 + 2 x 45 | 50 | 534 | 28 | 4160 x 2200 x 3630 | ok. 17000 |

| FS 160160 | 2 x 30 + 2 x 45 | 50 | 534 | 32 | 4360 x 2200 x 3630 | ok. 18000 |

| FS 160200 | 2 x 30 + 2 x 45 | 50 | 534 | 36 | 4560 x 2200 x 3630 | ok. 19000 |

Shredders for plastics, commonly known as shredders are used to shred and crush a wide range of waste, ranging from plastics in the form of adhesives, films, profiles to all kinds of waste from paper, cardboard, wood, metals, textiles, etc.