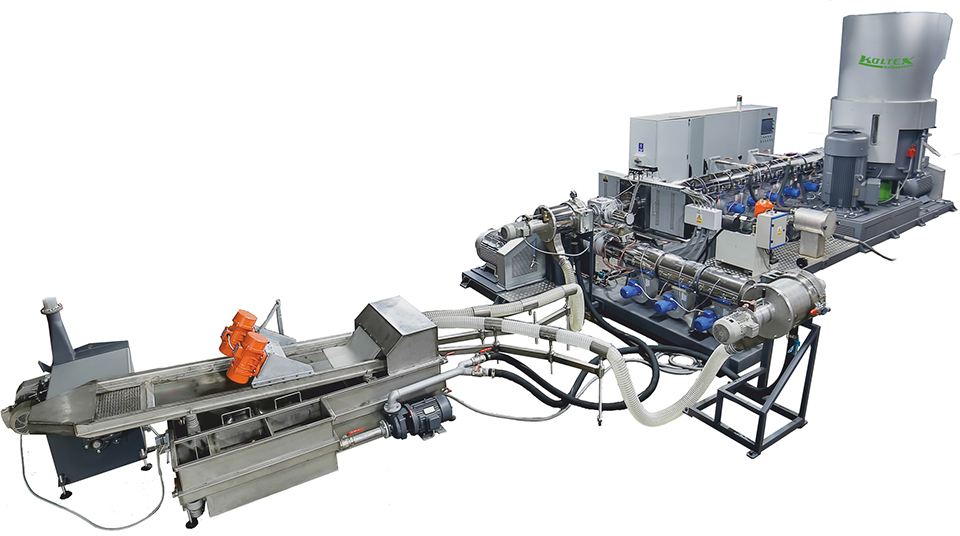

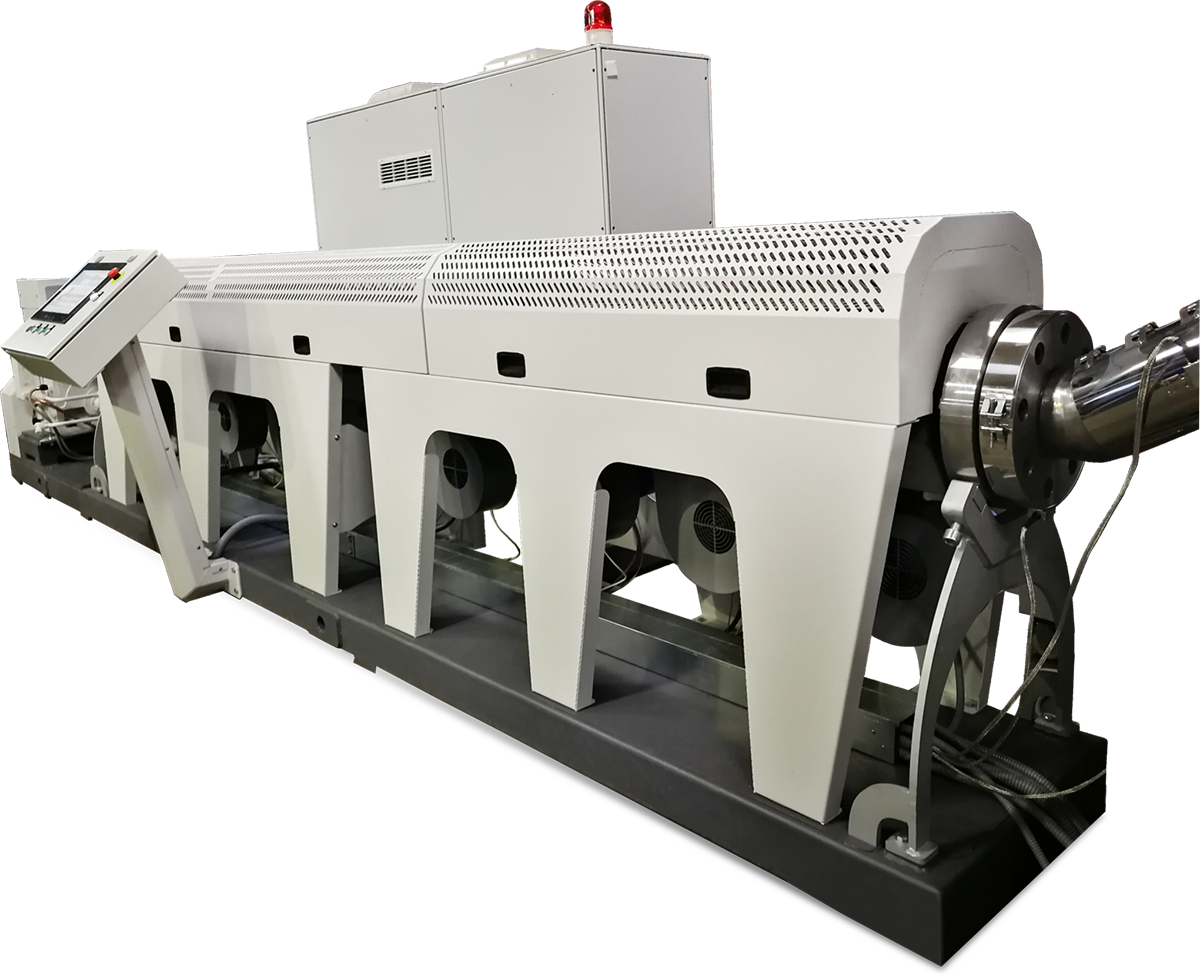

Compactors for plastics

Our equipment is subject to general and specific safety regulations and complies with CE requirements. Our offer includes compactors of the GHZ series.

The compactor makes it possible to process material of various shapes and sizes. The compacting of the material in the compactor consists in preparing the input material for operation in the plasticizing system of the extruder by pre-compaction and heating by friction of the material, which makes it possible to process also more printed and wet materials. The advantage of using thickeners is the possibility to process materials with low density of input material.

- TECHNICAL DATA

Table of compactor configurations

| Model | Compactor Engine Power [kW] | Capacity [liters] | Rotary Knives [pcs] | Fixed Knives [pcs] | Capacity [kg/h] |

|---|---|---|---|---|---|

| BSL-100 | 37 | 75 | 2 | 6 | 100 |

| BSL-200 | 55 | 150 | 2 | 6 | 150 |

| BSL-300 | 75 | 225 | 2 | 8 | 200 |

| BSL-500 | 90 | 375 | 4 | 8 | 300 |

| BSL-600 | 110 | 450 | 4 | 8 | 400 |

| BSL-800 | 132 | 600 | 4 | 8 | 550 |

| BSL-1500 | 160 | 1200 | 6 | 11 | 750 |

Compactors, also called compactors or agglomerators, are devices feeding

extruders, designed to reduce the volume (agglomeration) in the process of

granulation of shredded non-wovens, chips, film flakes and milling waste

materials such as PP, PE, LLDPE, LDPE, PS or ABS.