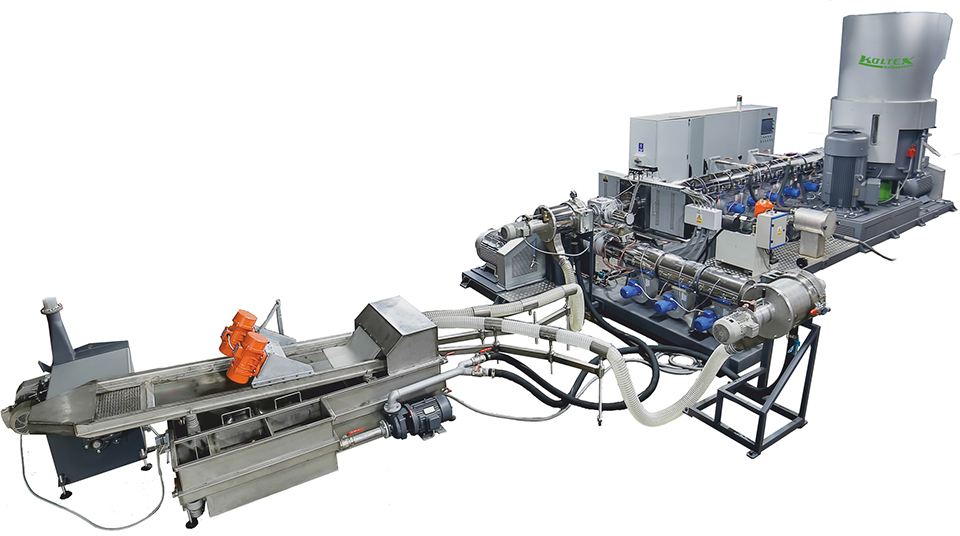

Granulation lines with a hopper

Specificity of production and extrusion of the processed bulk material, determines in addition to the design and dimensions of the plasticizing screw (in this case with a larger outer diameter than in the case of film extrusion line with a compactor), also the screw speed as well as the installed motor power.

The mechanism of the double degassing system allows for effective removal of gases from the extruded material and guarantees a proper quality of the granulated product, free from defects in the form of air bubbles. The use of drawer hydraulic screen changers ensures adequate filtration of the processed material.

Achieving the expected size and output of granules obtained depends strictly on the water mist cutting head adapted to the size of the material granules it processes. The required final moisture of granules is achieved by the granule drying centrifuge and the post-drying vibrating table located at the end of the line.

The entire granulation line production process is controlled through the HMI operator panel, where the operator is able to view the process parameters on an ongoing basis and change these parameters “online”. Additionally, the control enables remote access to the machine for management or service.

Our pelleting lines are subject to general and specific safety regulations and comply with CE requirements. We encourage you to get acquainted with our offer concerning granulating lines with hopper KL-K series.

- TECHNICAL DATA

| Model | Extruder motor power [kW] | Screw diameter [mm] | Screw length [L/D] | Filter mesh diameter [mm] | Output [kg/h] |

|---|---|---|---|---|---|

| KL-K/80 | 75 | 80 | 44 : 1 | 150 – 200 | 200 – 300 |

| KL-K/100 | 110 | 100 | 44 : 1 | 200 – 250 | 350 – 450 |

| KL-K/120 | 160 – 250 | 120 | 44 : 1 | 250 – 300 | 500 – 700 |

| KL-K/140 | 250 – 280 | 140 | 44 : 1 | 300 | 600 – 900 |

| KL-K/160 | 250 – 355 | 160 | 44 : 1 | 300 – 2 x 300 | 850 – 1100 |

| KL-K/180 | 355 – 500 | 180 | 44 : 1 | 300 – 2 x 300 | 1000 – 1500 |

| KL-K/200 | 400 – 500 | 200 | 44 : 1 | 300 – 2 x 300 | 1500 – 2000 |

Granulation lines with a hopper in the plastic recycling process are designed for granulation of comminuted, lightly printed free-flowing plastics such as PP, PE, PS, ABS, EPS in the form of milling. Equipping extruders of this line with square feeding hopper with attached mixer guarantees direct feeding of input material to plastifying system of the machine. The use of a single-screw plasticizing system, appropriately selected extruder length and screw pitch, combined with double vacuum degassing ensure high quality of the final product.