Belt conveyors

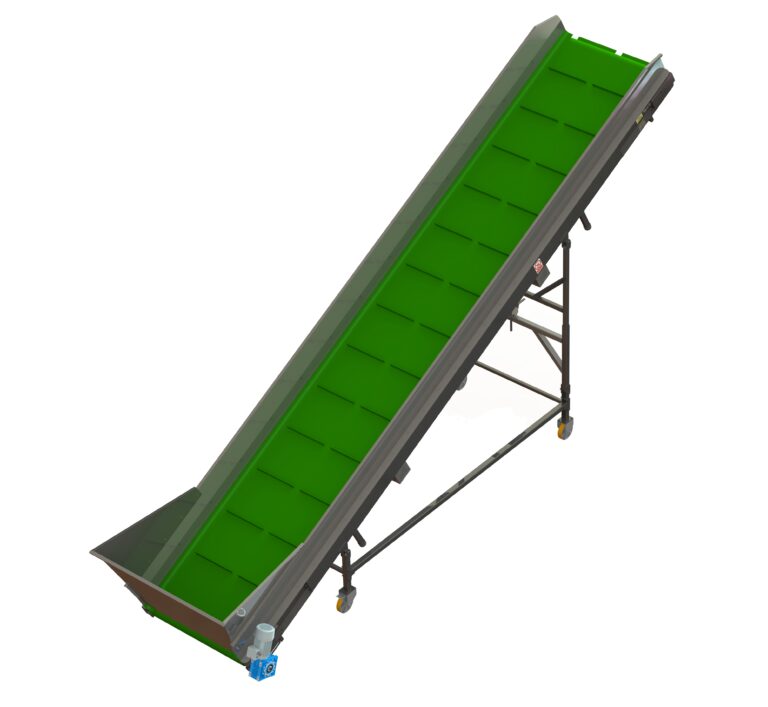

The construction of belt conveyors consists of frames made of stainless steel. The connection of frames by means of bolts and profiles with mounting holes make it possible to easily modify and extend the feeders with additional accessories such as sensors controlling their operation or metal detectors.

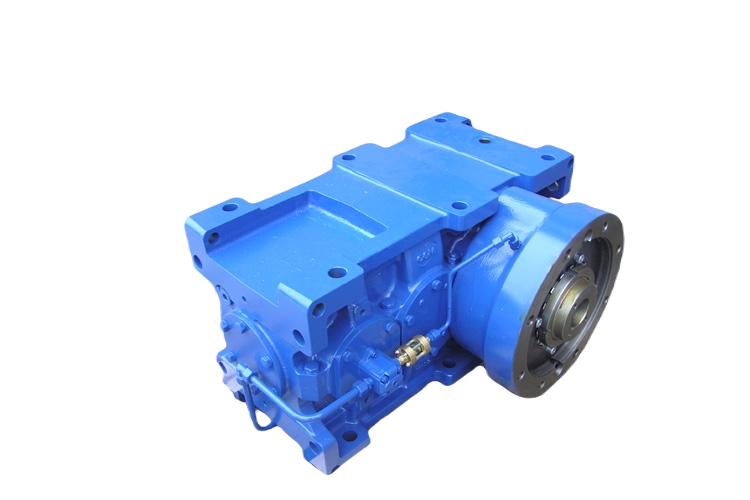

Appropriate adjustment to height and angle of inclination is carried out by adjusting the conveyor’s legs and telescopic supports as well as height adjustment on the feet at the base. The optimal material transfer is ensured by the drive shaft driven by a geared motor and by the conveyor belt made of PVC or PU, which is equipped with collectors and limited by the protective board. The work of belt feeders is controlled by a control cabinet (not included in the feeder) integrated with the work of other devices of the plastics recycling line.

We offer our customers a wide range of belt feeders from renowned manufacturers adapted to particular stages of processing on plastic recycling lines.

Belt conveyors are the most frequently used devices to transport processed materials on plastic recycling lines in order to ensure an optimum flow of these materials at individual recycling stages. Depending on the type of transported material, capacity, spatial conditions and other individual needs, a characteristic feature of belt feeders is the possibility of free and simple configuration and adjustment to the technical parameters and needs of production lines.