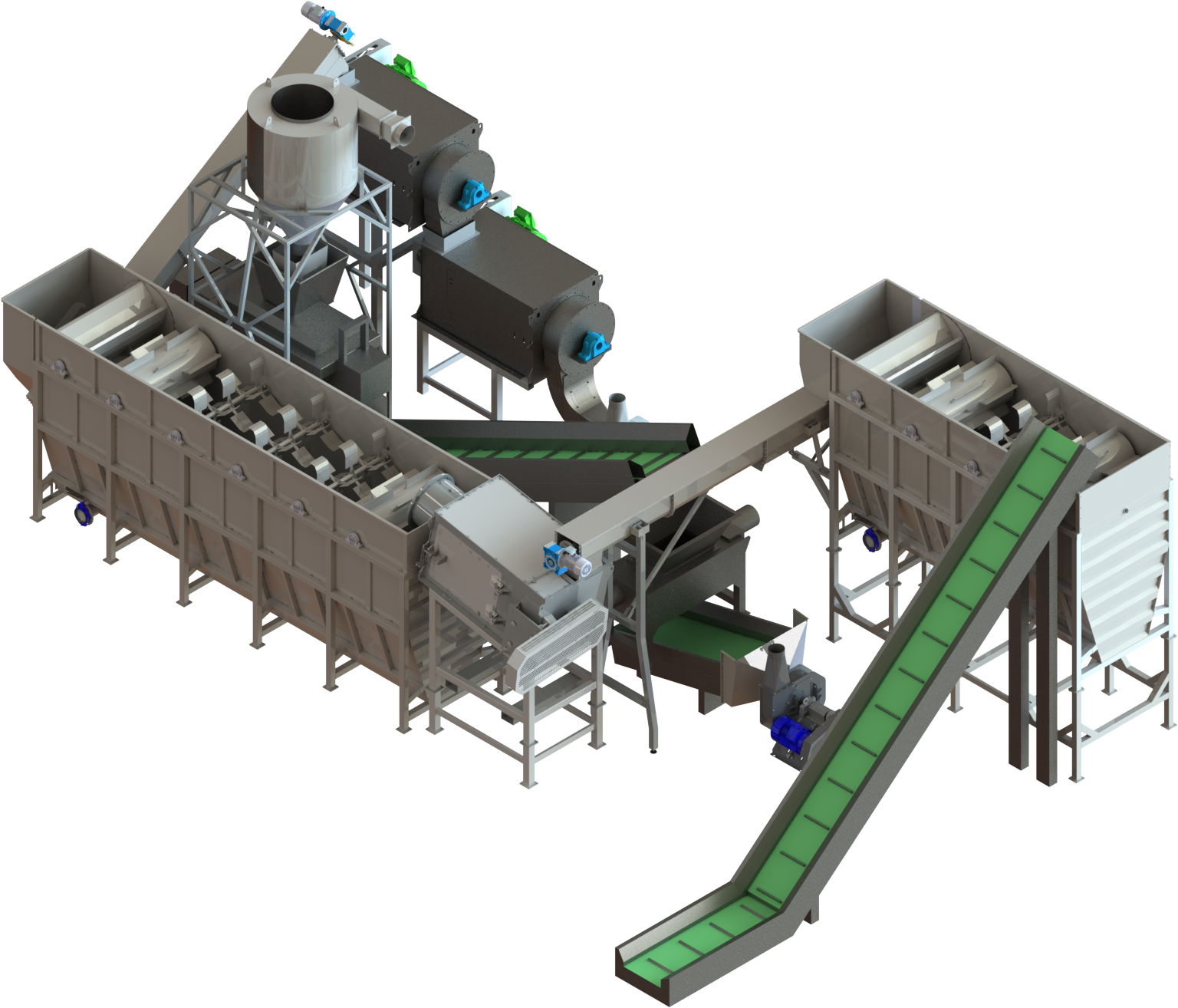

Dynamic washers

In our offer you will find KL-MD series dynamic washers and washers in cascade system (tandem). Our washers are subject to general and special safety regulations and comply with CE requirements.

The dynamic washers are used to wash the majority of lightly and moderately soiled and fragmented plastic waste such as PP and PVC packaging, PET bottles, LLDPE films, household chemical waste and are most often applied after the preliminary washing stage in preliminary washers. Therefore, dynamic washers should not be used interchangeably with pre-washers for washing heavily soiled (with sand, stones, etc.) waste. The washers offered by the masses are easy to operate and reliable devices which can be configured into more effective washing – dynamic cascade system (tandem – 2 x 30 kW or 2 x 55 kW). Multi-point water dosing to the screen washers (cleaning system) and active discharge of contaminants ensure more efficient operation, while dynamic charge movement is possible thanks to the rotor equipped with rotating blades. The extended part of the screen (1400 mm) significantly influences the quality of washing and the removal of excess water is possible due to the use of acid resistant steel screen. The use of 2 sieve segments provides the washer with better technical service.

- TECHNICAL DATA

| Model | Model Motor power [kW] | Foil washing capacity [kg/h] | Milling washing capacity [kg/h] |

|---|---|---|---|

| KL-MD/500 | 30 | 700 | 2 500 |

| KL-MD/1000 | 55 | 1 400 | 4 500 |

In plastics recycling, the washing process often requires multiple uses in order to make the processed material safe and suitable for further use. Application of a wider range of washing devices – dynamic washers, cascade washers, flotation tanks allows for more efficient separation of contaminated waste such as: sand, stones, metals, sinking PET etc. from plastic materials for further processing.