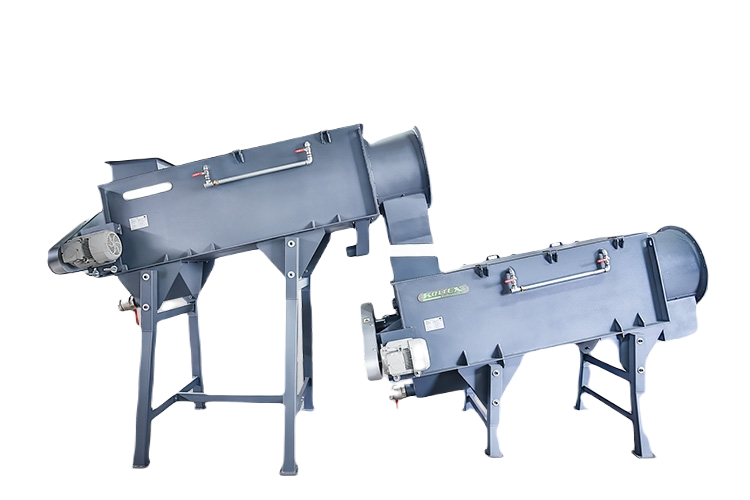

Flotation tanks

Flotation tanks are each time designed and configured according to individual customer requirements. Our tanks are subject to general and specific safety regulations and are in accordance with CE requirements.

The construction of flotation tank is a tank filled with water, which initially washes and separates floating and sinking material. Displacement of floating, crumbled material on the surface of the tank is possible thanks to the use of a system of stirrers (flotation machines) and sieves and blades mounted on them. Equipped with appropriate horizontal and vertical worm feeders, it is possible to continuously remove impurities from the bottom of the tank, and the cleaned material is discharged with water to centrifuges, which additionally enables ongoing water circulation in the tank. A better separation result is obtained thanks to a longer retention time of the material in the flotation tank. With the help of tubs with increased length and width, it is possible to use them in a cascade system when the contamination is higher.

Flotation tanks are stainless steel separation tanks designed to separate heavily soiled, comminuted plastic waste from other materials with different densities (e.g. plastic flakes from sinking PET bottle particles) and contaminants such as sand, stones, metals, etc.